Aluminum wiring

Due to the rapid rise in the price of copper, aluminum wiring first appeared in homes around 1965, until about 1976. Note that these aluminum electrical wires are still accepted today and are often used for some installations due to its lower cost than copper :

- Main electrical input

- Power supply of the electric furnace

- Cooker

Aluminum cables should be larger in diameter than copper. For example, a 12 AWG copper cable should be 10 AWG aluminum (larger). It is not the aluminum wiring that is problematic, but rather the connections as well as the type of outlet, switches or light fixtures that are connected to it. According to the CMEQ (Corporation of Master Electricians of Quebec), aluminum wiring is just as safe as copper wiring. On the other hand, aluminum wiring requires more attention.

Are aluminum wires problematic?

The aluminum wiring is not dangerous in itself, if the installations have been done properly by a master electrician in accordance with the standard of practice. It is when the installation is inadequate with the use of sockets and switches not designed for this purpose as well as copper / aluminum connections which are not made adequately that the risks of overheating, electric arcs and fire are possible.

Electrical outlets, switches, and even twist-on connectors, which can be found in stores, are for the most part CU-certified (copper only). The costs of "CO/ ALR" certified units are much more expensive (designed to be connected to aluminum wiring). When an aluminum wire is connected to a CU-approved socket, the risk of galvanic corrosion due to contact with two different metals is present which may result in an electric arc and / or overheating and thus a risk of fire, over time.

What to do if I have aluminum wiring in my house?

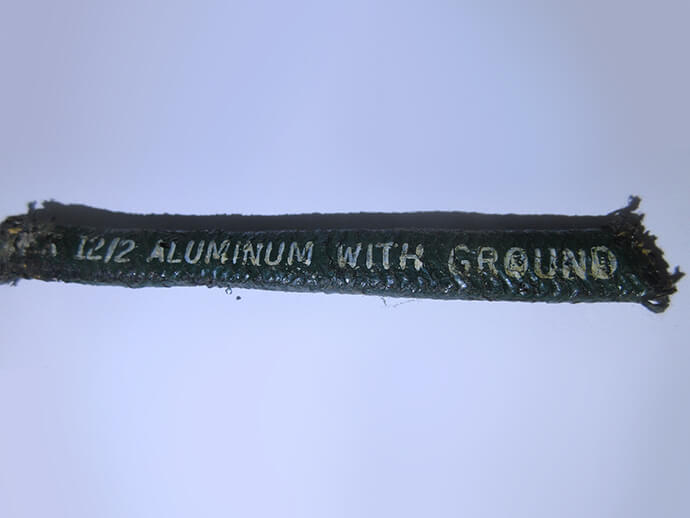

This type of wiring has a sheath that is often white with the mention "AL" or "ALUMINUM" inscribed, but the sheath is sometimes green or blue. If you notice their presence, the first step is to contact a master electrician to check the electrical installations. Most insurers will systematically require this audit and some companies will simply refuse to insure for this type of wiring. It is best to check with your insurance company to ensure that coverage is adequate in the event of a claim.

How to correct inadequate installations?

COPALUM fittings or crimps

-The first method is to replace all the aluminum wiring with copper cables, but this operation can be very expensive and often openings in the walls and ceilings will be necessary. On the other hand, during major renovations, it may be advantageous to replace everything that is accessible.

-Another way is to use COPALUM fittings or crimps. This again requires a master electrician with a specialized tool to install the fittings. Redoing all the connections of a house with COPALUM crimp can cost about half the cost of replacing with copper wiring throughout the building.

Example CO/ALR electrical outlet

-For sockets and switches, always use those approved "CO/ALR" which are designed to be connected directly to the aluminum cables. For multi-strand cables, the application of antioxidant paste is required to counter the risk of oxidation.

-Note that the use of decora-type rectangular electrical outlets (approved for copper cables only), with the use of antioxidant paste, is not an approved method and may involve significant risks.

Signs of problems

- Flashing lights

- Presence of unusual static in the TV

- Electric arcs coming from electrical sockets and switches

- Switches or protective plates that feels hot to the touch

- Circuit breakers that engage without good reason

- Insulated sleeves blackened or melted near connections

- Smell of burning or smoke present near switches, electrical sockets, junction boxes

- Lights that burn quickly or shine more than normal

In summary, if you notice the presence of aluminum wiring in your home, immediately hire a master electrician to review all the electrical installations in your home.